A milling vise is the perfect tool for you. It is a versatile and reliable device that can help you achieve precise results with minimal effort. In this comprehensive guide, we will discuss the different types of milling vises available, the benefits they offer, and factors to consider when choosing one for your workshop. Read on to learn more about how a milling vise can make your job easier and more accurate.

What is a Milling Vise

Milling vises are an essential tool for any machinist vise or hobbyist who needs to accurately hold and position their workpieces. A milling vise is a specialized type of clamp that securely holds the material being worked on, allowing for precise cutting and drilling. It consists of two flat, parallel jaws that are connected by a screw-operated mechanism. These jaws can be adjusted to accommodate different sizes and shapes of workpieces, providing a secure grip without damaging them. The adjustable clamp jaws also allow for fine-tuning of the cutting depth and angle, making it easier to achieve precise results. Milling vises are available in both manual and powered versions, making them suitable for any size job.

Benefits of a Milling Vise

Milling vises are essential for any workshop, offering a secure hold on parts and materials while you work. They provide greater accuracy when machining or drilling and allow for more precise movements with less effort. The adjustable jaws of a vise can be quickly altered to fit a variety of sizes and shapes, meaning you don’t have to constantly switch out tools. Additionally, the use of a milling vise can save time and money by increasing productivity. By securely holding your workpiece in place, it eliminates the need for clamping or other methods that could take up unnecessary time. Finally, using a this type of vise helps reduce material waste as it ensures that your part is held firmly in place while cutting or drilling. All in all, having a reliable milling vise in your workshop is an invaluable asset.

Choosing the Right Milling Vise

Choosing the right milling vise can be a daunting task with so many options available on the market. But luckily, there are some key factors to keep in mind when selecting a modern vise that will best suit your needs. Firstly, you should consider what size and type of material you’ll be working with—this will help narrow down the types of vises available. Once you have an idea of what size range is needed, determine if your vise should have adjustable jaws or fixed jaws; this will depend on how often you need to change the part sizes. Finally, look for features such as swivel bases and built-in rulers as these can offer additional convenience and accuracy when drill bit, surface grinder, machining or drilling. When it comes to finding the perfect milling vise for your shop, taking these points into consideration will help guide you in making an informed decision.

Factors to Consider When Choosing a Milling Vise

When it comes to selecting the right milling vise for your shop, there are a few factors to keep in mind. First, consider what size and type of material and material costs you’ll be working with—as this will help narrow down the types of vises available. Then decide if you need adjustable jaws or fixed jaws; adjustable jaws make it easier to change part sizes quickly, while fixed jaws are more stable and offer better accuracy. Finally, look for additional features such as swivel bases and built-in rulers for increased convenience and accuracy when machining or drilling. With just a little research, you’ll be able to find the perfect milling vise for your workshop.

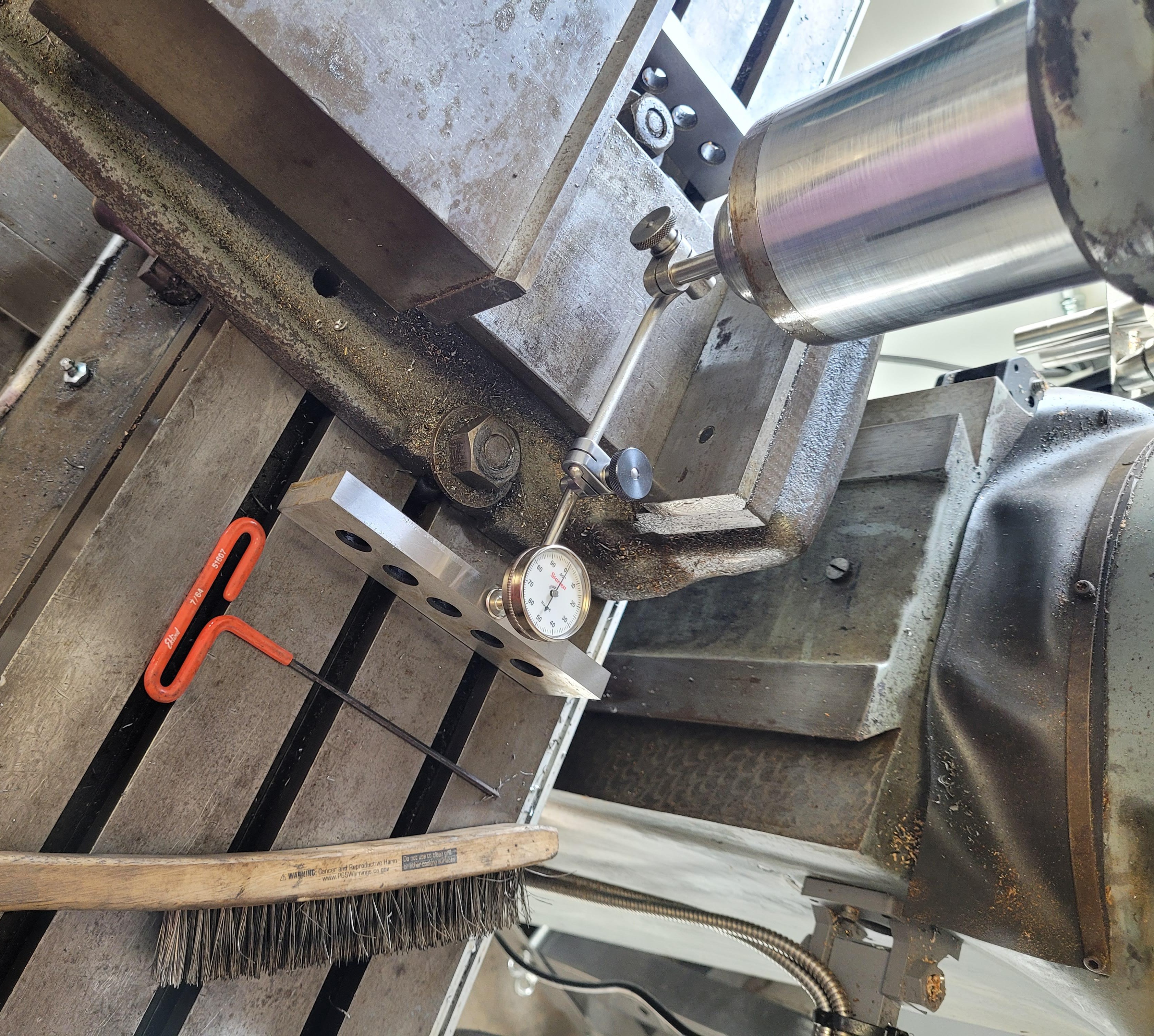

Clean and Tram the Milling Vise for optimal performance

Cleaning the table and trimming your milling vise are important steps to ensure accurate machining results. To clean the table, first remove any debris or residue using an air gun and a soft cloth. Then wipe down the surface with a damp cloth to remove any dirt or grime. Once the T-Slot table is clean, you’ll need to check the tram of your vise – this ensures that it is properly aligned with the machine’s spindle and prevents uneven cuts. The best way to do this is by using a dial indicator; simply place it on the jaw of your vise then adjust it until you get a true reading. With these simple steps, you can ensure that your milling vise is ready for accurate and precise machining.

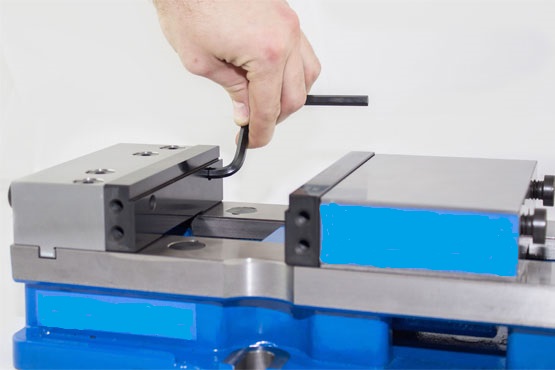

Vise Parallels and Jaw Steps

Vise parallels and vise jaw steps are must-have tools for any workshop. They provide the perfect height for your workpieces, as well as more repeatability due to less of the workpiece being gripped. Vise parallels are ideal for setting a workpiece high in the jaws, providing access to the piece and allowing it to be machined more accurately. On the other hand, jaw steps can be machined or purchased with a step already machined on them, which is also great for setting the workpiece high in the vise. Both options do an excellent job of providing stability while still giving you easy access to your workpieces. With these two tools in your arsenal, you’ll be able to ensure that each part that comes out of your workshop is accurate and precise.

Techniques for jaw health and wellness

Maintaining the health and wellness of your milling vise’s jaws is essential for successful machining. Here are some simple tips to help keep your vise in top condition:

Inspect the jaws regularly for signs of wear or damage. If any parts need to be replaced, do so as soon as possible. Make sure that the jaws are clean and free from burrs or nicks before use – a wire brush can come in handy here. Use jaw covers when not in use, which will provide an extra layer of protection against chips and debris. Lubricate the moving parts of your vise on a regular basis with something like light machine oil to ensure smooth operation and reduce wear over time.

Double Station machinist Vise

A Double Station Machinist Vise is an incredibly useful tool for any machinist vise. These vises allow you to work on two pieces at the same time, saving you time and effort. Most double station vises have four jaws that are adjustable so that you can customize the width of each piece you’re working on. They also come with a swiveling base, allowing easy access to both sides of the vise. You can also get magnetic extensions for a double station vise, making it even easier to move your workpieces around quickly and accurately. With a double station machinist vise, you’ll be able to finish more projects in less time than ever before.

Quick Change Jaws

Quick Change Jaws are a great way to save time and hassle when working in the shop. They allow you to quickly and easily switch out different jaws for different jobs, saving you the time and effort of having to manually change out each jaw. In addition to saving time, Quick Change Jaws also provide a higher level of accuracy than traditional manual jaws. This is because they are designed with special features that allow them to tightly fit into their respective vise jaw slots, reducing any potential play or slop that can occur with manual jaws. Finally, many Quick Change Jaws come with preset stop points which make it even easier to adjust the tightness of the jaw in just one quick turn. With all these benefits, it’s no wonder Quick Change Jaws have become such a popular choice among machinists.

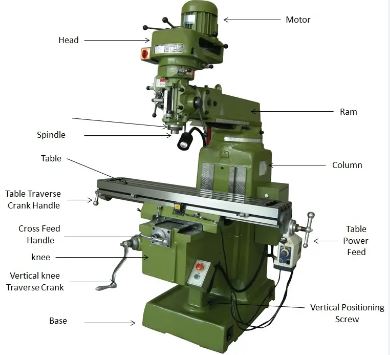

What are the Parts of a Milling Machine

Milling machines are essential tools for many metalworking and woodworking projects, but knowing the key parts of a milling machine is critical for successful operation. The motor is responsible for powering the machine, while the column provides support for the spindle, which rotates at high speeds to cut material. The base supports the entire device, ensuring that it remains stable during work. Finally, the monitor allows you to adjust settings and control operations from afar. With these four primary components, a milling machine tools can be used to shape and fabricate objects with precision and accuracy. Understanding how each part works together is essential not only for effective operation of your milling machine but also for achieving an optimal outcome on your project.

Overview of Milling Vise and their Applications

Milling vises are one of the most important tools you can have in your workshop, as they allow you to securely hold and manipulate materials while using a milling machine. They come in a variety of sizes, shapes and styles, so it is important to understand the different types and uses for each. Generally speaking, there are three main categories of milling vises: precision vises, standard vises and heavy machining vises. Precision vises offer precise alignment and control when working with small parts. Standard vises are well-suited for general purpose machining jobs such as slotting or drilling metals. Finally, heavy duty vises are made of high quality cast iron construction designed to withstand heavier loads like those encountered when cutting steel. With the right milling vise you can safely and accurately produce intricate items with precision results.

Milling Machine Safety Rules

When working with milling machines, safety should always be at the forefront of your mind. With a few simple rules and guidelines, you can ensure that your workshop remains safe and accident-free. Here are a few essential safety tips to keep in mind whenever you’re using a milling machine:

• Always wear the appropriate personal protective equipment (PPE), such as ear protection, eye protection, footwear, and gloves.

• Be sure to read the owner’s manual for your particular machine tools before using it.

• Make sure the workpiece is secured firmly in the vise before starting any machining operations.

• Keep hands away from cutting tools at all times.

• Use the correct cutting speed for the material you are machining.

• Don’t attempt to adjust or repair any machine parts while power is on.

• Ensure that all work surfaces are clear of debris and obstructions.

By following these simple guidelines, you’ll be able to keep your workshop safe and productive for years to come.

FAQ’S on Milling Vise

What are the elements of Milling vise?

Milling vises are an indispensable tool for any workshop, and understanding the various elements of a milling vise can help you make the best choice for your needs. The most basic element of a milling vise is its jaw, which is the portion of the vise that normal clamps onto the workpiece. All vises will have two jaws: a fixed jaw and a movable jaw. The base is the part of the vise that attaches to your machine tools table, and it may include a swivel base for added maneuverability. Other elements can include a handle, an adjustable angle plate ,one of popular fixture plate stop and a scale for precise positioning.

What are the different types of Milling vises?

There are several types of milling vises available. The most common type is the standard milling vise, which is designed for general-purpose machining, such as drilling and slotting. Precision vises are made for more intricate work with smaller parts or fine adjustments. Heavy-duty vises are designed to stand up to tougher applications such as cutting steel. Finally, universal vises contain adjustable jaws that make them suitable for a variety of tasks.

Why do we need to stop vises?

It is essential to stop your vise when milling as this will ensure that your workpiece is securely held in place. If the vise is not securely clamped down, it can cause the material to move and slip while you are machining it, resulting in inaccurate cuts and potentially damaging the workpiece. Stopping your vise will also ensure that the cutting tool remains in contact with the material at setup times, which is essential for optimal cutting performance.

What equipment is used for milling?

When it comes to milling, there are several pieces of equipment that can be used. The most important is the milling machine itself, which comes in many different varieties and sizes depending on your needs. Other essential items include a vise , a drill press vise, end mills, drill bit, cutting tools and measuring tools. Depending on the job, you may also need additional items such as a rotary table or a tapping head.

What is a clamp in a milling machine?

Using a clamp in a milling machine is an important part of using the machine safely and accurately. A clamp acts like a vise, holding your workpiece firmly in place while you’re machining it. CNC Clamps are available in a variety of sizes, shapes and materials so you can find the perfect one for your application. It’s important to select the right clamp for your workpiece so that it can be held securely without damaging the material.

Conclusion

When it comes to milling vises, there’s no shortage of options available on the market. From double station machinist vises with adjustable jaws and magnetic extensions, to quick change jaws and heavy duty cast iron construction, there’s a vise that can meet almost any need. No matter what type of work you do in your workshop, having the right milling vise for the job will ensure that your projects are completed with accuracy and precision. Plus, by following a few simple safety rules you can ensure that you remain safe while using these powerful tools. With so many great options available, it’s easy to find the perfect milling vise for your workshop.